How Modern Seedling Transplanting Works

The image of a person plowing their fields with oxen and a harrow is a thing of the distant past. This labor-intensive work has been almost entirely taken over by large agricultural machines, which farmers can operate comfortably. These machines are now indispensable—the demand for food and feed has reached new heights, necessitating the cultivation of fields and greenhouses on an unprecedented scale. Da Ros Srl, an Italian company, specializes in manufacturing agricultural machinery for nursery and vertical farm. One of their tools, a transplanter, provides assistance in day-to-day operations, as do the FAULHABER drive systems that are incorporated in this machine.

With more automation and robotics in agriculture, the way food is grown is changing significantly. This brings numerous benefits, including improved efficiency and productivity, as well as more sustainable and environmentally friendly farming practices. Additionally, automation reduces physical strain and enhances safety for workers by handling heavy, repetitive, and physically demanding tasks. Not least, the use of robots and machines helps address labor shortages. Continuous technological innovation is crucial not only for staying competitive in the market but also for meeting the increasing demands of Industry 4.0.

Smart Farming with the Transplanter

Thanks to advanced devices and machines, areas or individual plants can be precisely managed according to specific conditions. Smart farming allows sections or entire areas to be cultivated in a computer-assisted and automated manner. Networked processes ensure ease of use and efficient workflows.

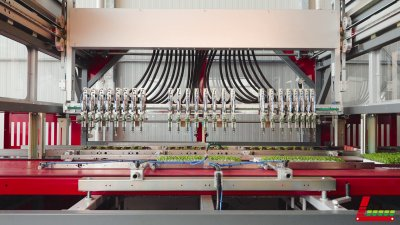

One of the machines offered by Da Ros is the new transplanter, the “TRAPIANTATRICE Model TP-24.” Suitable for all types of horticultural, floral, and forestry plants. It carries out the transplant operation using special grippers, taking the seedlings from the small cells of the germination trays without damaging them, and then placing them in trays with larger spaces, which support the continuation of the growth process. However, even modern machines and systems face challenges that must be overcome to maximize productivity in precision agriculture. They need to be quickly and easily set up and must operate accurately and reliably, especially for repetitive tasks.

The Italian company Da Ros Srl is dedicated to the design, construction, and commissioning of highly functional agricultural machines. Founded in 1986, the company addresses the requirements, workflows, and unique challenges faced by the agricultural sector. With innovative technologies and modern products, Da Ros offers solutions for automation and optimization aimed at sustainable and efficient farming. Whether sowing, transplanting, potting, or watering, their high-performance machines provide not only standard solutions but also alternative and customized options for diverse agricultural needs.

When FAULHABER Assists in Planting

FAULHABER drive systems are used for optimal gripper handling in the TP-24 transplanter. Thanks to their compact size and high dynamics, the minimum distance between individual grippers is just 22 mm, allowing up to 24 grippers to fit in the machine. A brushless motor from the 2250…BX4 series with integrated feedback and a planetary gearhead from the 22GPT series ensures reliable gripper operation. The gearbox is characterized by a high continuous torque and a high speed. Thanks to these speeds, the machine can work extremely productively. Control is managed via a FAULHABER Motion Controller MC 5004 P, which communicates via EtherCAT. The machine is also designed with a modular concept, enabling easy adaptation to different customer production requirements.

The Da Ros team is impressed: “We were looking for a small brushless motor. At FAULHABER, we found expertise and helpfulness, especially in the early stages of the project when we were unsure about the application specifications. From the beginning of the project to its commissioning, we were supported by a qualified and competent team that advised us on selecting the best products for our technical requirements.”